our history

see where we've been and where we're going

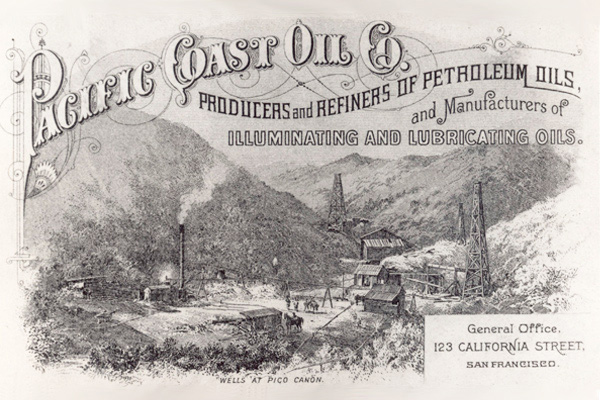

Our company has a long, robust history that began when a group of explorers and merchants established the Pacific Coast Oil Co. on September 10, 1879.

Since then, our company’s name has changed more than once, but we’ve always retained our founders’ spirit, grit, innovation and perseverance.

leading the way

Chevron's earliest predecessor, Pacific Coast Oil Co., was incorporated in 1879 in San Francisco. The first logo contained the company name against a backdrop of wooden derricks set among the Santa Susana Mountains that loomed over Pico Canyon. This was the site of the company's Pico No. 4 field, California's earliest commercial oil discovery.

the quest for black gold

Spurred by memories of the gold rush, hordes of prospectors descended on California in the 1860s, seeking another kind of bounty – black gold, or oil. Their early efforts were fruitless.

Undeterred, petroleum pioneers Demetrius Scofield and Frederick Taylor of the California Star Oil Works, a Chevron predecessor, took aim at Pico Canyon, a remote portion of the rugged Santa Susana Mountains. In September 1876, driller Alex Mentry succeeded in striking oil in Pico No. 4.

The first successful oil well in California, Pico No. 4 launched California as an oil-producing state and demonstrated the spirit of innovation, ingenuity, optimism and risk-taking that has marked the company ever since.

Lacking the capital it would need to seize marketing opportunities in this growing area, California Star was acquired by the Pacific Coast Oil Co. (PCO), which led to PCO’s new incorporation on September 10, 1879.

Within the next year, PCO built its first refinery at Point Alameda on San Francisco Bay; constructed a pipeline that linked Pico Canyon with the Southern Pacific’s train station at Elayon in Southern California; and undertook an extensive, largely successful drilling program.

In 1895, the company initiated its enduring marine history when it built California’s first steel tanker, the George Loomis, which could

ship 6,500 barrels of crude between Ventura and San Francisco.

a new force enters the region

In 1878, Standard Oil Co. opened a three-person, second-story office in San Francisco. Despite its modest trappings, Standard possessed marketing acumen, outstanding products, an aggressive advertising philosophy and financial backing from its New York parent.

By 1885, it consolidated its Western interests under its subsidiary, the Standard Oil Co. (Iowa), which controlled distribution stations throughout the West Coast.

Lacking Standard Iowa’s marketing savvy and financial clout, PCO in 1900 agreed to be acquired by Standard Oil Co. (New Jersey), while retaining the name of Pacific Coast Oil Co.

richmond’s colossal refinery

After buying 500 acres of rolling lands on the northeast shore of San Francisco Bay in 1901, the company completed the Richmond Refinery a year later. To feed this new colossus of West Coast refineries, it laid a pipeline from Richmond to the prolific new oil fields at Kern River and Coalinga.

a new entity is born

As the company grew, it changed structurally. In 1906, a consolidation between PCO and Standard Iowa created a new entity, Standard Oil Co. (California), finalizing an integration that had existed for six years.

The “new” company stepped up its marketing efforts, particularly in gasoline sales, which nearly doubled between 1906 and 1910, and lubricants, which were marketed under the Calumet, Diamond, Petrolite, Ruddy Harvester, Zerolene and Zone labels.

To meet the growing market for motor fuels, the company came up with a revolutionary new sales mechanism – the world’s first “service station,” started in Seattle by sales manager John McLean.

the first gusher

Until now, Standard had left the hunt for oil to others. In 1909, the company decided to gamble on its ability to find its own oil. After several initial failures, the drilling team had its first success on January 22, 1910, when a gusher flowed in at 1,500 barrels a day at the Midway-Sunset Field in Kern County, California.

going it alone

The company’s expertise in searching for oil became increasingly important as a May 1911 Supreme Court decision separated Standard Oil Co. (California) from its parent company, Standard Oil Co. (New Jersey).

Before the end of 1911, Standard Oil Co. (California) added to its refining capacity with the completion of the El Segundo Refinery in Southern California; formed the California Natural Gas Co. to expand its search for natural gas in the San Joaquin Valley and beyond; and constructed a second pipeline linking Richmond and the Kern River Field.

spirit of standard

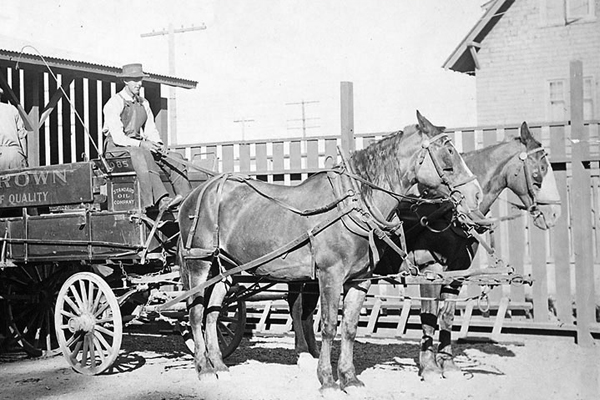

In this 1915 photo, a horse-drawn wagon loaded up at a Standard Oil Co. (California) station in Sausalito, Calif., for delivery of Red Crown Gasoline and Pearl Oil to customers in the San Francisco Bay area. Throughout the early decades of the 20th century, the company’s quality product line successfully served the U.S. West Coast market.

a strong company in a dynamic market

Divested from its parent company in 1911, Standard Oil Co. (California) had strong financial discipline, an impressive product line, marketing savvy, a growing refining system, a flexible marine fleet and an extensive pipeline network. One critical challenge remained: finding the energy to meet spiraling demand in a dynamic marketplace.

Fortunately, Standard had the right person for the job in Fred Hillman, who became director of the Producing Department in 1911. Within four years, Standard moved from sixth place to first among California’s oil producers. And by 1919, Standard’s production had grown to more than one quarter of the state’s total.

Hillman’s earliest oil and gas exploration successes came at Midway, where the company made seven discoveries in an 18-month period, including the largest, McNee No. 4, which produced a record 30,000 barrels a day in April 1912.

new reserves to meet growing demand

After moving into the Los Angeles Basin, Hillman led his exploration team in delivering five gushers at the Emery Field in the West Coyote Hills between December 1912 and October 1913.

By 1917, Standard had added two other great Southern California discoveries in the Montebello and Baldwin No. 3 fields.

The company’s efficiency and ability to find new reserves helped it keep pace with the surging demand for energy products that was fueled by the dramatic population growth and increased reliance on automobiles throughout Standard’s marketing area. In January 1919, the company had the first of several discoveries in Elk Hills in California’s San Joaquin Valley.

To serve markets in areas such as the Northwestern United States, Standard more than doubled its oceangoing capacity between 1912 and 1916 by adding five tankers. By 1926, the fleet grew to 40 vessels, including 22 oceangoing tankers as well as stern wheelers, launches, barges and tugs.

coping with increased competition

Standard Oil Co. (California) also steadily expanded its service station network. It became the Western leader by the end of 1919 with a total of 218 stations, more than the next three rivals combined. By 1926, the number of service stations in the company’s five-state marketing area more than tripled to 735 units.

Following upon the success of Red Crown automobile gasoline, Standard introduced Red Crown aviation fuel in 1918, promoting the product through advertisements and through wider commitment to the growth of the aviation industry.

Standard excelled in developing new products, such as the line of petrochemicals manufactured to support the Allied effort in World War I.

Standard turned increasingly to international markets to maintain its sales growth. Between 1911 and 1914, export sales rose from 14% to 28% of the total business.

a new name for a growing company

In 1926, Standard boosted its production capacity by almost 50% when it acquired Pacific Oil Co., an organization that handled the oil properties of Southern Pacific Railroad. The company marked this achievement by creating a new corporate structure with a new name – Standard Oil Co. of California, or Socal.

One of the hallmarks of the newly named company continued to be the respect and fairness with which it treated its employees. This tradition of enlightened human relations dated back to the company’s founders, who espoused favorable wages, hours and working conditions for all company employees.

honoring the ‘standard oil spirit’

The fair treatment of company employees had a direct payoff in morale. In 1919, 94 percent of the employees who had served in World War I returned to work for the company at a time of high employment and opportunities for workers.

Recognizing the cooperation and mutual confidence throughout the company, President Kenneth Kingsbury in 1923 described this all-important attribute as the “Standard Oil Spirit.”

in war and peace

As the growing highway system encouraged longer car trips during the 1920s and 1930s, Standard service stations attracted motorists by adding such amenities as clean, well-appointed restrooms and drinking fountains. With the introduction of the Standard Lubrication System, as well as Atlas tires, headlight bulbs and standardized battery service, the stations offered a complete one-stop service.

a far-flung search for new reserves

With U.S. crude oil supplies depleted by the Allies’ military needs during World War I, Socal began seeking oil and gas reserves beyond U.S. shores in the postwar years. The long, intrepid quest would take more than 10 years before the company made its first international discovery in June 1932.

Undeterred, Socal focused on the Middle East, an area with no history of discoveries and no obvious petroleum prospects. The company gained its first foothold in the region in 1928 when Gulf Oil Corporation offered its Bahrain concession to Socal.

After surveying the island, geologist Fred Davies and producing superintendent William Taylor selected a 12-mile-long ovalshaped depression called Jabal ad Dukhan, or the “Hill of Smoke,” because its 453-foot mound was the highest point on the island. Working in searing heat, the team met with success on June 1, 1932.

next stop, Saudi Arabia

Also in June 1932, Socal began a year-long series of negotiations with the Saudi government before the two sides signed a concession agreement providing the company with exploration rights for the next 60 years over an area of about 360,000 square miles.

After geologists surveyed the concession area, they identified a promising site and named it Dammam No. 1, after a nearby village. Over the next three years, the drillers were unsuccessful in making a commercial strike, but chief geologist Max Steineke persevered.

He urged the team to drill deeper, even when Dammam No. 7 was plagued by cave-ins, stuck drill bits and other problems, before the drillers finally struck pay dirt on March 3, 1938.

the birth of caltex

Socal already had a potential market for its Middle Eastern oil by creating a historic partnership with Texaco in 1936.

The joint venture, which became known as the California Texas Oil Company, or Caltex, melded the company’s Middle Eastern exploration and production rights with Texaco’s extensive marketing network in Africa and Asia.

The joint-venture partners also agreed to share exploration rights in Central Sumatra, Java and Dutch New Guinea, which had been granted to Socal in 1935.

During the prewar years, Socal’s aggressive exploration program extended to the Southeastern United States, where the California Company, a Socal subsidiary, made its first discovery at Bayou Barataria, Louisiana, in 1939.

moving forward in difficult times

To offset the Great Depression’s dramatic impact on earnings, the company stimulated sales by bringing out solidly researched new products, including Standard Gasoline in 1931, DELO oils in 1935 and RPM Motor Oil in 1936.

fueling the war effort

With the entry of the United States into World War II in December 1941, Socal became a key supplier of crude oil and refined products for the Allies in the Pacific.

Meeting a key need for a more efficient aviation fuel, the company spent more than $57 million to expand 100-octane plants at the Richmond and El Segundo refineries and converted the Bakersfield Refinery almost exclusively to 100-octane production.

World War II also created a boom in petrochemical demand. Socal invested more than $9 million to boost production of synthetic toluene – the second “T” in TNT.

During this time, women broke new ground, playing increasingly important roles in offices, laboratories, refineries, service stations and, occasionally, oil fields.

The efforts of employees received much praise from U.S. military and government leaders, such as General Douglas MacArthur, who wrote: “To the men and women of Standard Oil of California: We, the soldiers of the firing line, give thanks to you soldiers on the production line for the sinews of war that [made] our victory possible.”

a new identity

A Standard Oil geologist examined a rock specimen in the Venezuelan Andes in 1958, where there was an effort to build on the discovery of oil at the country’s Boscan Field a decade earlier. During the years following World War II, the company mounted an aggressive exploration program, which led to discoveries as far ranging as the U.S. Gulf of Mexico, Canada, Saudi Arabia and Indonesia.

focusing on worldwide exploration

The resumption of peace following World War II infused Socal with new energy, new opportunities and an enterprising quest for new oil and gas resources.

And the company’s high exploration success rate helped to maintain its position as the third-largest oil producer in the United States and the No. 1 producer in California. Particularly encouraging news came from the jungles of Sumatra, where the company learned that the Japanese occupying force had actually struck oil at Minas No. 1, using a rig left behind by Caltex Pacific Indonesia when crews vacated the area in 1941.

In late 1949, when Caltex Pacific finally resumed development of the field, the company realized that Minas was an oil giant, which would yield 1 billion barrels over a 17-year period, from 1952 to 1969.

In the decade following the war, Socal’s major U.S. discoveries included the Kelly-Snyder Field in West Texas; the Main Pass, Bay Marchand and Romere Pass fields in the offshore waters of the Gulf of Mexico, where the company became the largest oil producer as of 1949; and the Rangely Field in the Rockies of Colorado.

pioneering in petrochemicals

In the postwar period, the company built on its position as a major supplier of petrochemicals by developing a wide array of new products.

In 1951, the company created the Oronite Chemical Co. to market a growing output of petrochemicals. Three years later, the Richmond Refinery became the nation’s first unit to

manufacture paraxylene, a basic material for making Dacron® and other synthetic fibers.

an era of growth

Reflecting Socal’s growth in these postwar years, revenues surpassed $1 billion for the first time in 1951. This growth continued, initially topping $2 billion in 1961 and climbing to almost $6 billion by 1969.

Throughout this period, Socal developed a wide range of new products, including Chevron and Chevron Supreme Gasoline, introduced in 1945; RPM motor oils in 1950; and Chevron Custom Supreme, the first three-grade gasoline in the West, in 1959.

extending the market

Socal’s marketing reach now extended far beyond the original five-state base in the Western United States. After acquiring the Perth Amboy Refinery in New Jersey in 1945, the company used it as a manufacturing base a couple of years later when it launched an expanded marketing network in 12 Eastern states through its subsidiary, California Oil Co.

U.S. expansion continued in 1961 when the company merged with Standard Oil Co. (Kentucky), the market leader in petroleum products in five Southeastern states. To serve this market with crude oil from fields in the Gulf of Mexico, the company constructed the 100,000-barrel-a-day refinery in Pascagoula, Mississippi, in 1963.

a new presence in Europe

In Western Europe, Socal agreed to dissolve the Caltex structure in that area and split its operations between the two parent companies, Socal and Texaco.

Paralleling the growth in marketing and producing operations, the company enlarged and diversified its manufacturing capabilities in the Eastern and Western hemispheres. At the Richmond Refinery in 1965, the company launched the world’s largest Isomax hydrocracking complex, which converted heavy petroleum oils to light stocks used to make gasoline and other products.

overcoming political disruptions

During the 1970s, the petroleum industry was confronted by many political issues – from the 1973 oil embargo to the nationalization of company assets by Libya, Venezuela and other oil producers.

Nevertheless, the decade was marked by numerous milestones, including major discoveries ranging from the West Pembina Field in Alberta, Canada, to the Ninian Field in the United Kingdom North Sea.

*Dacron® is a federally registered trademark of E.I. Du Pont de Nemours and Company.

market expansion

As Socal began its second century, it had become a major company in the United States and the Chevron brand was becoming familiar around the world. The company had ownership in 50 refineries, with a production capacity of almost 3 million barrels per day, and featured the third-largest fleet among oil companies worldwide.

The company experienced strong results during the early 1980s, such as major discoveries and large acquisitions of offshore acreage in the U.S. Gulf of Mexico, a $1 billion modernization of its Pascagoula Refinery and the introduction of new Chevron Supreme Unleaded Gasoline with Techroline.

And yet the larger picture was unsettling, prompting the company to conclude that its normal business strategies simply wouldn’t be enough.

The company’s chance to expand came virtually overnight. Gulf Oil Corp., the nation’s fifth-largest petroleum company, had warded off a takeover bid, prompting Gulf’s board of directors to offer the company up for sale.

On March 5, 1984, Socal Chairman George Keller made a bid of $80 per share, roughly $13.3 billion, and hours later received a phone call from Gulf Chairman James Lee, telling him that Socal had won the bidding.

With a price tag of $13.3 billion, it was the largest merger in corporate history at the time – and a strong marriage of assets, corporate philosophy and the varied talents of two

organizations’ employees.

By acquiring Gulf, Socal nearly doubled its worldwide proved oil and gas reserves overnight.

Through the merger, Socal added major exploration and production operations in areas where it was already strong, such as the U.S. Gulf of Mexico, Canada and the North Sea.

In West Africa, Gulf’s foreign reserves suddenly lifted the company to a leading position.

With the merger came a new name for the company: Chevron Corporation – the name by which gasoline and other products had been known for decades in the United States and under which the company operated in many non-U.S. locations.

a smooth integration

Through the Gulf merger, Chevron became the No. 1 U.S. refiner and marketer as well as the nation’s market leader in gas liquids.

By 1988, when the company acquired $2.5 billion in properties from Tenneco, Chevron became the leading oil and gas producer in the U.S. Gulf of Mexico.

shifting priorities

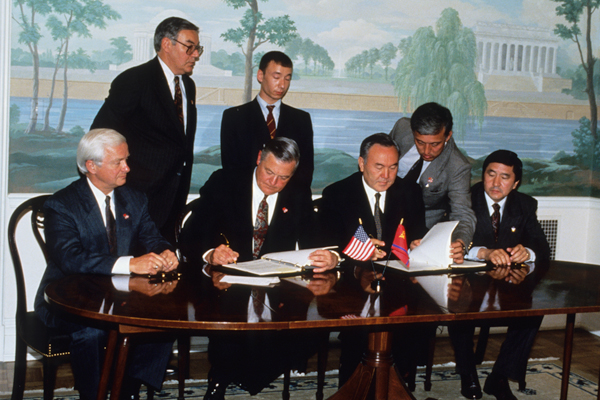

In the early 1990s, as U.S. exploration opportunities shrank, Chevron shifted its emphasis increasingly toward international projects, such as the development of the huge Tengiz Field in Kazakhstan after forming a partnership with that country’s government in 1993.

The company’s strategies clearly were paying off. In 1996, earnings hit an all-time high of $2.6 billion, and production of more than 1 million barrels a day was the highest in 11 years.

Chevron’s ability to grow through alliances was an important factor in its success – and an acknowledgment that the industry’s best opportunities often involved mega-projects that required the resources of more than a single corporation.

a long affiliation

After forming a corporate Mergers and Acquisitions group in January 1998, Chevron began evaluating other companies that might best complement its own. Based on a long affiliation with Texaco dating back to the 1936 formation of a joint-venture company, Caltex, Chevron rated Texaco high as a potential merger partner.

In 1999, Chevron initiated a series of talks with Texaco, which proved unsuccessful.

The following year, Chevron renewed talks with Texaco. On October 16, 2000, the two companies announced that they had reached an agreement to merge. Nearly one year later, on October 9, 2001, the shareholders of Chevron and Texaco voted to approve the merger, and ChevronTexaco Corp. began doing business that same day.

The company became the second largest U.S.-based energy company, with more than 11 billion barrels of oil and equivalent gas reserves and 2.4 million barrels per day of refining capacity.

a new era of energy

Chevron began production from its Tahiti Field, the deepest producing field in the U.S. Gulf of Mexico, in May 2009. One of the largest crude oil and natural gas reservoirs in the gulf, the field was developed after the company used 3D imaging signals to penetrate 2-mile-high layers of salt and visualize the full extent of the field.

In the months that followed the creation of ChevronTexaco, the new company found itself looking for resources in ever-more-difficult environments – deeper, more remote and increasingly complex fields and underground reservoirs with more challenging characteristics.

“The era of easy oil is over,” said then Chairman and CEO David J. O’Reilly.

From 2002 to 2007, the company earned close to $72 billion. During that same period, the company invested roughly the same amount to bring new energy supplies to market.

The company remained a leader among its peers, averaging a 42% success rate for exploration wells from 2002 through 2007. Chevron’s exploration program added approximately 1 billion barrels to its resource base over that same time period.

adding unocal

In 2005, the company changed its name to Chevron Corp. and then acquired Unocal Corp., further enhancing its position as a leading energy provider. The acquisition was a strong strategic fit, strengthening the company’s exploration and production portfolio in the Asia-Pacific, the U.S. Gulf of Mexico and the Caspian region. The addition of Unocal provided a deep source of talent and leading-edge technology that Chevron quickly integrated throughout its organization.

Technology offered a key advantage in the search for new energy supplies. Fully integrated across the company – from exploration to product delivery – Chevron’s technology success derived from a combination of proprietary capabilities and strong partnerships.

Chevron demonstrated its expertise in employing deepwater exploration technology in the U.S. Gulf of Mexico. In 2006, the Jack well test set more than half-a-dozen world records for pressure, depth and duration in deep water. Five miles deep, it was the deepest well ever tested in the gulf. And these records were achieved without a single safety or environmental incident.

Also in the U.S. Gulf of Mexico, Chevron achieved first oil from the Tahiti Field in May 2009. In approximately 4,100 feet (1,250 meters) of water, Tahiti featured the deepest producing well in the gulf.

Three-dimensional visualization technology gives geologists a virtual tour through the rock, deep underground, and allows them to “see” potential reservoirs. This technology was employed at the Tahiti Field and at the Tengiz and Karachaganak fields in Kazakhstan.

The company used its expertise in reservoir management to complete a major expansion project that nearly doubled production capacity from the giant Tengiz Field in Kazakhstan. The project – called the Sour Gas Injection/Second Generation Plant – took five years and $7 billion to complete.

The Tengiz expansion and the ramp-up of the deepwater Agbami Field offshore Nigeria were two projects that added significant production volumes in 2009. Discovered in 1998, the Agbami Field is a subsea development with wells tied back to a floating production, storage and offloading vessel.

focusing on the long-term upstream growth

The development of a substantial queue of major capital projects was central to Chevron’s focus on long-term growth and creating significant shareholder value for decades to come. This trend continued with the startup of four major capital projects in 2012: the deepwater Usan Field and Agbami 2 offshore Nigeria and Caesar/Tonga and Tahiti 2 in the U.S. Gulf of Mexico. Consistent with the company’s record of previous technological firsts, Tahiti 2 set several individual records for increasing deepwater production through the use of water injection, an effective method of enhancing reservoir pressure to reach additional oil.

In pursuit of its long-term focus, Chevron continued to advance its two world-class liquefied natural gas (LNG) projects in Western Australia, Gorgon and Wheatstone. The Gorgon Project achieved key construction milestones and delivered first gas in April 2016. Gorgon’s progress continued, with the first delivery of gas at Train 3 in March 2017. And by 2019, Chevron Australia completed the Carbon Dioxide (CO2) Injection Project, which involved the design, construction and operation of facilities to inject CO2 into a deep reservoir more than two kilometers beneath Barrow Island. By permanently trapping the CO2, Chevron expects to reduce greenhouse gas (GHG) emissions from the Gorgon Project by approximately 40%, or more than 100 million tonnes over the life of the injection project.

Meanwhile, the achievement of several commercial milestones helped lead to the startup of the Wheatstone Project in October 2017. “First LNG production is a significant milestone and is a credit to our partners, contractors and the many thousands of people who collaborated to deliver this legacy asset,” said then Chairman and CEO John Watson.

The large queue of discoveries in Australia’s Carnarvon Basin contributes to the resources available to sustain Chevron’s LNG projects in the region.

Across the globe, Chevron continued progress on the company’s development projects to deliver future production growth. In 2015, Chevron achieved first production at the Lianzi Project in the Angola–Republic of the Congo Joint Development Area, the Moho Bilondo Phase 1b Project in Republic of the Congo and the Agbami 3 Project in Nigeria.

In 2016, Chevron ramped up production at the Jack/St. Malo Project in the U.S. Gulf of Mexico. Jack and St. Malo are two of the largest oil and gas fields ever discovered in the deepwater gulf, with reservoirs more than 26,000 feet (7,925 meters) deep, under 7,000 feet (2,134 meters) of water. With a capacity of 177,000 barrels of oil equivalent per day, the Jack/St. Malo floating production unit is the largest operation that Chevron has in the Gulf of Mexico.

Chevron’s development of oil and natural gas from shale and tight rock formations intensified when the company entered the Marcellus Shale through its acquisition of Atlas Energy in 2011. By 2017, the company was also developing tight oil or liquids-rich gas shales in the Permian Basin of the Southwestern United States the Vaca Muerta Shale in Argentina and the Duvernay Shale in Canada. Production from our shale and tight rock activity in the Permian Basin exceeded expectations, driven by innovations in well design, applications of new technology, continued improvement in well drilling and completions, and an increase in long-lateral well inventory. With approximately 2.2 million net acres of resources in the Permian Basin, Chevron was one of the basin’s largest net acreage holders. By the end of the decade, the Permian Basin was forecast to reach one million barrels of oil-equivalent production per day in 2025.

Across Chevron’s asset base, the Upstream business continued to grow. In 2018, the company reported a highest-ever worldwide net production of more than 2.9 million oil-equivalent barrels per day, up more than 7% from 2017 and 12% from 2016. Production increases were driven by Permian Basin growth, startups in the Gulf of Mexico and Australia, continued ramp-up of LNG operations in Australia, and a high level of reliability at Tengizchevroil (TCO) in Kazakhstan. The company added approximately 1.46 billion barrels of net oil-equivalent proved reserves, replacing 136% of production, and had a five-year reserve replacement ratio of 117%.

In 2019, Chevron’s Upstream business delivered record production once again even as the company streamlined its operational and geographic footprint. Chevron produced 3.06 million oil-equivalent barrels per day in 2019, up more than 4% from 2018. And the company embarked on changes to enhance its ability to compete in any price environment by driving efficiencies, evolving its portfolio and optimizing the value chain.

downstream and chemicals reimagined

The global restructuring of the company’s Downstream & Chemicals (DS&C) business has delivered greater value from a more tightly focused portfolio. From 2010 through 2015, Chevron ranked No. 1 or No. 2 among its peers in earnings per barrel and return on capital employed. In 2015, Chevron’s Downstream segment reported its best year on record, with $7.6 billion in earnings. The company has also become a leading global producer of premium base oil since the 2014 completion of a base oil facility at the Pascagoula, Mississippi, refinery.

DS&C ended the decade on a strong note, strengthening its position in key markets. Chevron Phillips Chemical Company announced agreements with Qatar Petroleum to jointly develop new petrochemical plants. Chevron enhanced its U.S. Gulf Coast value chain by purchasing the Pasadena Refinery, enabling the company to process Permian crude. And Chevron signed an agreement to acquire Puma Energy (Australia) Holdings Pty Ltd. When the acquisition was completed in 2020, Chevron added a network of more than 360 company- and retailer-owned service stations, a commercial and industrial fuels business, and owned and leased seaboard import terminals and fuel distribution depots.

delivering energy around the globe

Transportation is an essential part of Chevron’s operations. Chevron Pipeline and Power and Chevron Shipping Company manage safe, reliable, flexible and efficient systems that deliver energy to Chevron’s customers around the globe. In 2017, Chevron’s Midstream organization achieved a significant milestone by delivering the first LNG cargo from Wheatstone to customers in Japan. The company also completed the largest shipbuilding and fleet modernization program in recent Chevron history, taking delivery of its fifth and sixth LNG carriers. And in 2018, Chevron’s Shipping organization supported the safe and successful delivery of the first modular component of oil field equipment to the Future Growth Project in Kazakhstan, a major expansion of the Tengiz Field, due to start up in late 2022.

leading the future of energy

Chevron Shipping Company employees inspect a liquefied natural gas (LNG) storage tank under construction in South Korea during the company’s largest shipbuilding and fleet modernization program in corporate history. The program included delivery of seven new ships to support growing LNG operations.

The 2020s have brought interlocking challenges, driven by a pandemic and the major fall in energy prices. Fortunately, Chevron was prepared to respond.

“Even before COVID-19, we were preparing to lead in a future marked by change,” said Chairman and CEO Mike Wirth. “Our actions were proactive and disciplined – simplifying and modernizing work; integrating teams, processes and value chains across business units and geographies; elevating leadership capabilities; advancing digital solutions; and empowering our workforce to make decisions quickly, safely and with greater accountability.”

When market conditions deteriorated in 2020, Chevron swiftly reduced capital spending by 35% from 2019 and reduced operating costs, reflecting a commitment to both capital and cost discipline. In the Permian Basin, the company demonstrated its flexibility to cut short-cycle capital. Chevron also undertook internal transformation efforts to become more agile, cost efficient and streamlined.

The 2020 acquisition of Noble Energy added complementary high-quality assets in Texas’s Permian Basin, Colorado’s DJ Basin and the Eastern Mediterranean. Portfolio additions in 2020 included approximately 5.67 million net exploration acres.

Chevron added 832 million barrels of net oil-equivalent proved reserves in 2020, with the largest net additions coming from the Noble Energy acquisition. Portfolio growth included 36 exploration blocks in various regions in the U.S. Gulf of Mexico, Egypt, Canada, Colombia and Cyprus in 2020 and early 2021. Production in the Permian Basin increased 29% over the prior year to 574,000 barrels of oil-equivalent per day. And despite the challenges presented by the COVID-19 pandemic, TCO advanced construction of the Future Growth Project/Wellhead Pressure Management Project.

During that period, the company sold a range of assets, extending from its Central North Sea United Kingdom upstream assets to the company’s operations in Azerbaijan.

In addition to acquiring Puma Energy, DS&C also marked the new decade with several highlights. The company advanced construction on the alkylation retrofit project at the Salt Lake City Refinery. GS Caltex, the company’s non-operated joint venture, progressed its olefins mixed-feed cracker project at the Yeosu Refinery in South Korea. And Chevron Phillips Chemical Company advanced its projects to develop petrochemical complexes in Qatar and the U.S. Gulf Coast.

what’s next for chevron?

In the decades ahead, the world will need all the energy that can be produced from every available source, including natural gas, crude oil, coal, renewables and nuclear. Chevron is committed to working safely and responsibly to help develop that energy through an unmatched array of major capital projects.

In 2020, Chevron developed an energy transition strategy to achieve a lower-carbon future, which will involve leveraging the company’s capabilities, assets and expertise to deliver measurable progress that is good for investors and good for society. Chevron’s actions are focused on lowering the company’s carbon intensity cost-efficiently, increasing renewables and offsets in support of Chevron’s business, and investing in low-carbon technologies to enable commercial solutions.

Chevron’s New Energies organization, formed in 2021, is focused on areas where the company can build competitive advantages and that target sectors of the economy that cannot be easily electrified. Hydrogen, as well as carbon capture, utilization and storage, and offsets are at the core of this strategy. These businesses support Chevron’s efforts to reduce its greenhouse gas emissions and are also expected to become high-growth opportunities with the potential to generate substantial returns.

Some examples of Chevron’s lower-carbon projects, partnerships and collaborations, all established in 2021, include a collaboration agreement with Caterpillar to develop hydrogen demonstration projects in transportation and stationary power applications, including prime power; and the expansion of Brightmark RNG Holdings LLC, a previously announced joint venture with Brightmark LLC, to own projects across the United States to

produce and market dairy biomethane, a renewable natural gas.

To deliver on the expectations of today while working to transform the energy system of tomorrow, Chevron’s strategy is clear: leverage its capabilities, assets and customers to deliver lower carbon energy to a growing world.