energy transition

we believe the future of energy is lower carbon

We all have a stake in a reliable and affordable energy system and a lower carbon future. This belief drives Chevron’s lower carbon ambitions and the actions we take to advance them.

our strategy

our strategy is clear

We’re leveraging our strengths to safely deliver lower carbon energy to a growing world.

We aim to lead in lower carbon intensity oil, products and natural gas, and advance new solutions to reduce carbon emissions of major industries.

our actions

lowering the carbon intensity of our oil, products and natural gas operations

advancing solutions with chevron new energies

explore our actions toward a lower carbon future

the energy transition needs solutions, scale and speed

our outlook

affordable, reliable, ever-cleaner energy is essential to achieving a more prosperous world

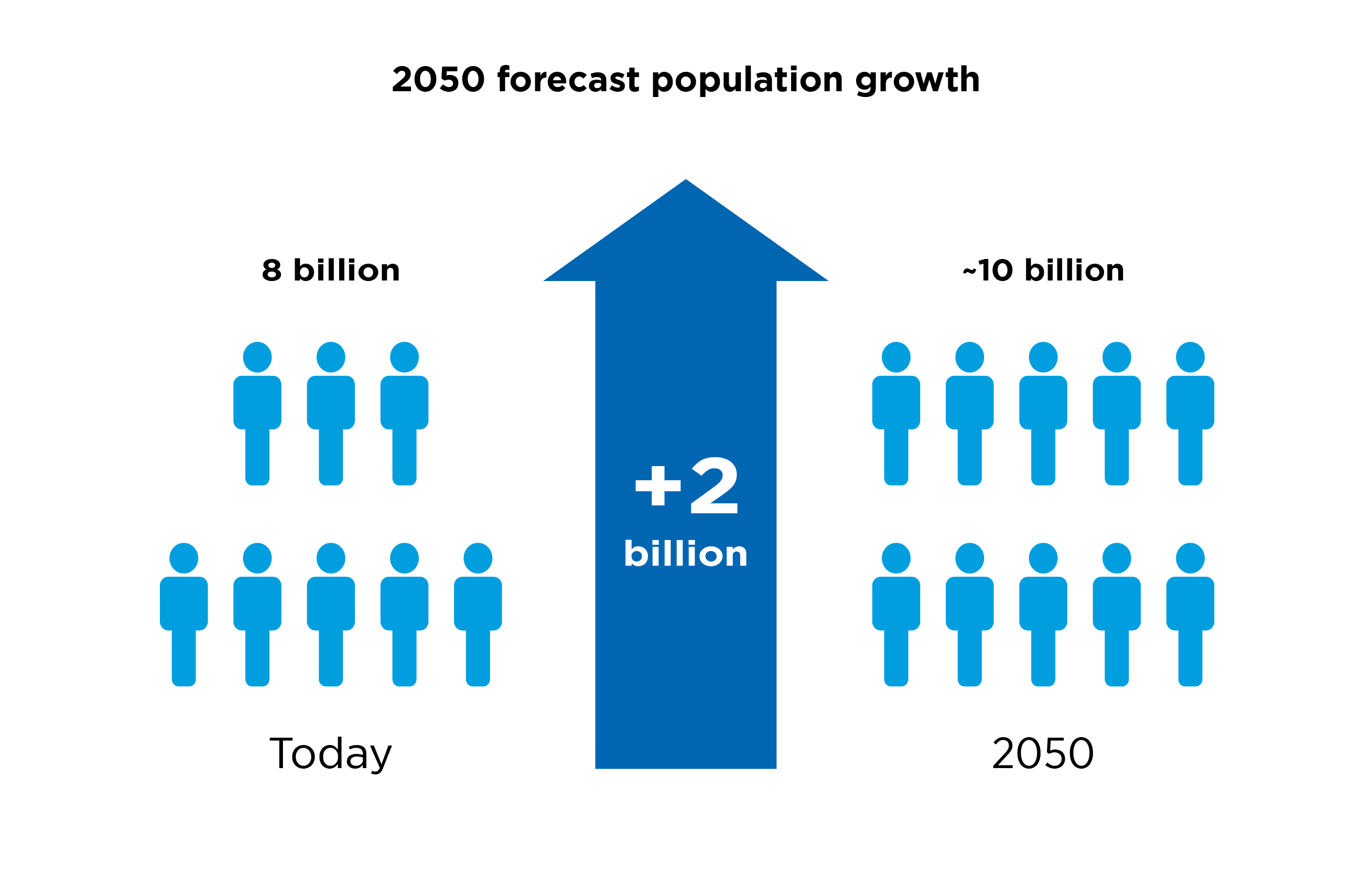

The world’s energy demand in recent years is greater than at any time in human history. We’re working to meet demand today while we help build the energy system of tomorrow.

enabling human progress

the future energy mix

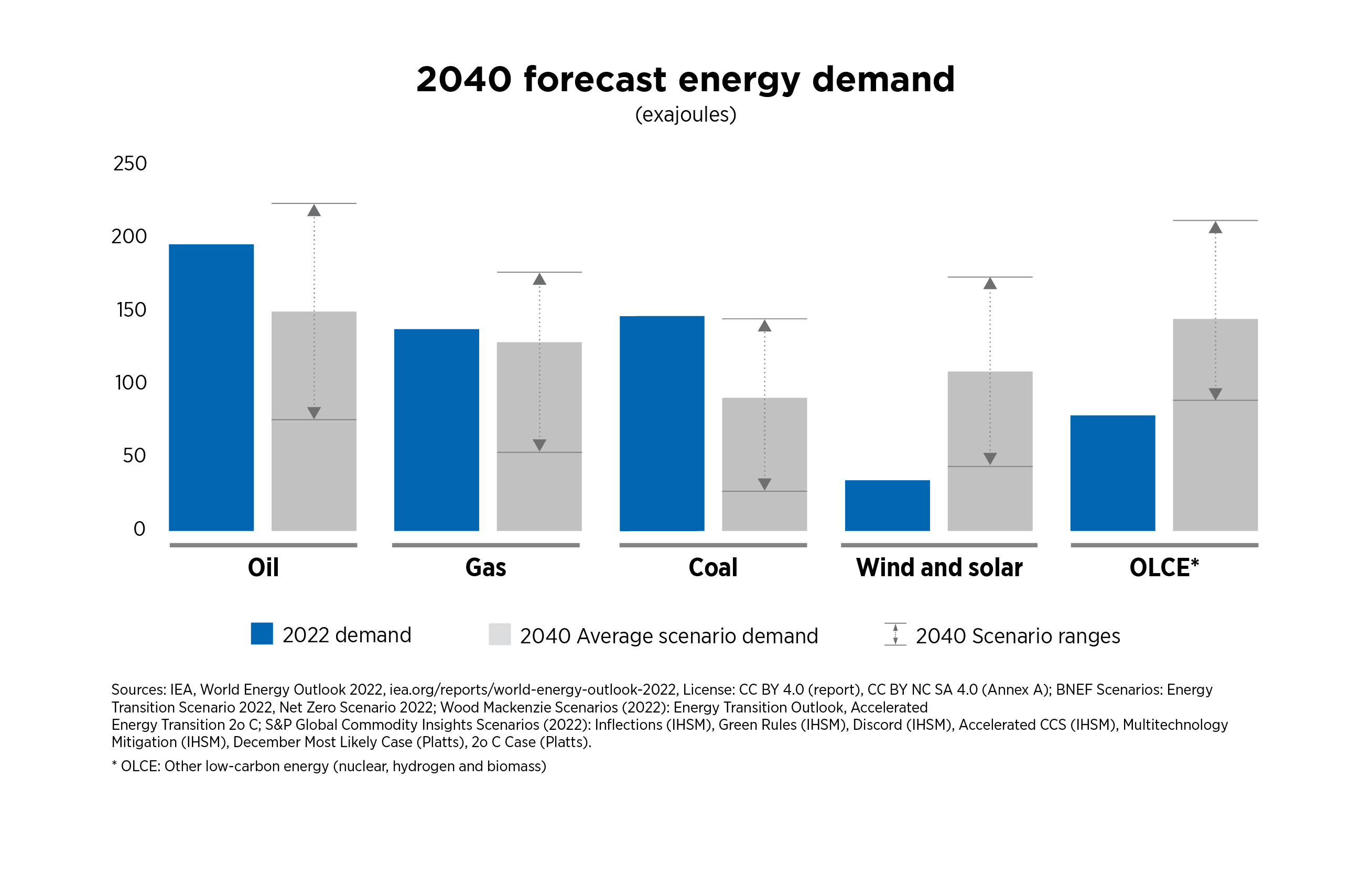

While there are many potential paths to a lower carbon future, many energy experts agree that a mix of energy sources, including oil and gas, will be required to satisfy global energy demand under almost any future market scenario.

Mike Wirth

Chairman and CEO, Chevron

our approach

a pragmatic conversation about energy

climate policy

Chevron supports well-designed climate policy. We believe that broad, market-based mechanisms are the most efficient approach to addressing GHG emissions reductions.

portfolio carbon intensity

We utilize a portfolio carbon intensity (PCI) metric that encompasses the full value chain carbon intensity of the products we sell, including our own emissions, emissions from third parties, and emissions from customer use of our products.

targets to lower the carbon intensity of our operations

portfolio carbon intensity (scope 1, 2 and 3) by 2028

gas carbon intensity

(scope 1 and 2) by 2028

oil carbon intensity

(scope 1 and 2) by 2028

refining carbon intensity (scope 1 and 2) by 2028

$10 billion

capital investments

We plan to invest $8 billion in lower carbon investments and $2 billion in carbon reduction projects by 2028.

executive compensation

Energy transition is one of four performance measurements in the Chevron Incentive Plan.

trade associations

Our political engagements are designed to support our ambition to deliver affordable, reliable and ever-cleaner energy.

partnership and investments

We’re collaborating in new ways and working toward innovations that help advance a lower carbon future.

chevron email updates

Subscribe to our newsletter to receive news and updates.