emissions solutions

lower carbon factors into facilities design

1 min read | june 03, 2022

Chevron Mustang-area operations in Colorado are proof that less is less. You read that right – less is less, not less is more. Through creative facilities design, we’re achieving “less” every day.

what less looks like

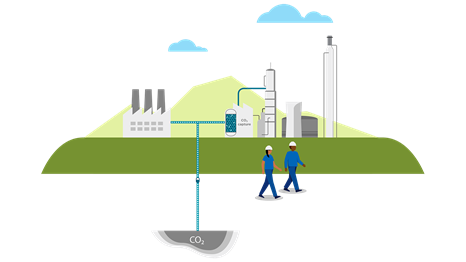

Our production facilities in the Mustang area are designed to reduce emissions by using a smaller surface footprint. We’re operating on just 7.5 surface acres to deliver the same oil and gas production volume that previously required 400 surface acres.

Because we’re producing direct to pipeline, we eliminate the need for space-consuming production tanks, flare systems and further downstream processing facilities. This design has the potential to lower our greenhouse gas emissions by more than 90% and can help us lower our carbon intensity cost efficiently.

the bottom line

The new facility design:

- Reduces our surface footprint by more than 95%.

- Is expected to reduce carbon intensity by up to 90%.

- Lowers life cycle costs by 15% to 20%.

- Helps eliminate more than 152 million miles of truck traffic and associated emissions.

how it’s done

This is all accomplished through electrical power, modern flowback technology and producing spec oil direct to pipeline.

more on that

Since 2019, we’ve drilled 56 wells using utility electric power. When possible, we use grid electricity instead of onsite generators to power the drilling rig, eliminating:

- 100% of nitrous oxides and other ozone precursor emissions in summer months.

- Approximately 75% in colder months, when operations require the use of boilers for heat.

and deeper

Learn about Chevron’s Mustang comprehensive drilling plan, a blueprint for lower carbon energy development.

topics covered

related content

-

explainer: what do we mean by hard-to-abate industries?

explainer: what do we mean by hard-to-abate industries?emissions solutionsmay 03, 2024

-

laying the foundation to realize carbon capture’s potential

laying the foundation to realize carbon capture’s potentialemissions solutionsmarch 27, 2024

-

hydrogen facility to be a chevron first

hydrogen facility to be a chevron firstour operationsfebruary 29, 2024

-

supply chains are part of the evolution in energy

supply chains are part of the evolution in energyemissions solutionsjanuary 11, 2024

chevron email updates

Subscribe to our newsletter to receive news and updates.