united states

powering progress

Headquartered in Houston, Texas, Chevron Corporation is one of the largest integrated energy companies in the United States. Our operations drive energy security, economic growth and innovation – while striving to deliver affordable, reliable, lower carbon energy to a growing world.

increase in U.S. production 2024

0

total investment in 2025

0

total investment in all 50 states since 2022

0

exploration and production

Chevron operates crude oil and natural gas fields in the United States – primarily in California, Colorado, New Mexico and Texas.

land operations

Across the United States, we’re using technology and innovation to help develop affordable, reliable, ever-cleaner energy.

In 2024, the Permian Basin, which straddles Texas and New Mexico, increased nearly 18% from 2023, accounting for a significant portion of our total U.S. production of 1.6 million boe per day.

Chevron’s oil and natural gas operations are in the Denver-Julesburg (DJ) Basin – a large geological formation primarily in northeastern Colorado.

We operate in seven fields in three counties – Kern, Fresno, and Monterey – that produce crude oil and natural gas, as well as electricity and steam. With thousands of productive wells, we are one of the largest oil producers in the state.

deepwater

Chevron is one of the leading producers in the Gulf of America, where we operate some of the world’s lowest carbon intensity oil and gas assets.

In 2024, we achieved a groundbreaking milestone with first oil from Anchor, our newest platform in the Gulf.

Jack/St. Malo is one of Chevron’s highest producing facilities in the Gulf of America

The Chevron-operated Big Foot platform has an estimated production life of 35 years and total potential recoverable oil-equivalent resources are estimated to exceed 200 million.

The Ballymore project is a 3-mile subsea tieback to the Blind Faith platform with a gross capacity of 75,000 barrels of crude oil per day.

Blind Faith, the host facility for the Ballymore tieback, is located 160 miles (258 km) southeast of New Orleans. It produces oil from wells in more than 6,000 feet of water.

The total production of the Chevron-operated Tahiti Field is enough to power 11.5 million homes in one year.

innovating for the future

We’re accelerating technology solutions to help safely deliver the lower-carbon energy the growing world demands today – while striving to build a lower-carbon energy system for the future.

lower-carbon intensity technologies

From carbon capture to geothermal technologies, we’re working to unlock the next generation of energy.

renewable fuels

We’re helping produce reliable, renewable fuels to help our customers achieve their lower carbon ambitions.

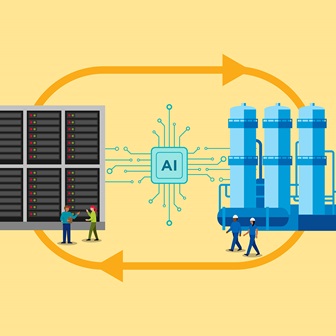

AI

We’re forging partnerships to supply reliable energy to AI data centers with natural gas.

more on innovation

marketing and retail

With 8,000+ Chevron and Texaco stations, we provide affordable, reliable fuel to millions across the US. We’re among the leading suppliers of jet and aviation fuels to commercial airlines, resellers, and the military.

Refining

Our five US refineries process one million barrels of crude oil daily, supplying fuels that power homes, businesses, and transportation across America.

products to power the country

Lubricants and base oils

Our line of solutions – including Havoline® and Delo® motor oils – are sold worldwide under our Chevron®, Texaco® and Caltex® brands. These premium products help customers across industries to improve or maintain fuel economy.

Chemicals and additives

Chevron is one of the world’s top producers of commodity petrochemicals, through the 50 percent-owned joint venture Chevron Phillips Chemical Company LLC (CPChem). Our Chevron Oronite Company LLC (Chevron Oronite) provides lubricant and fuel additives designed to enhance the reliability, efficiency and life of transportation and industrial equipment.

moving energy across america

Shipping

Chevron’s fleet has provided a vital link between our operations and the marketplace for more than 125 years.

Pipelines

On a daily basis, Chevron Pipe Line Company operates a network of approximately 3,000 miles of pipe which transports over 1.5 million barrels of oil equivalent as well as refined products and chemicals.

Power generation

Chevron Pipeline and Power provides comprehensive support services to improve the power reliability and energy efficiency of Chevron operations worldwide. Chevron is actively developing solutions for the energy systems of tomorrow. We’ve made strategic investments across lower carbon technologies like CCS, hydrogen and geothermal. We continue to evaluate emerging technologies that can reduce the carbon intensity of power solutions for the future.

in the community

Around the world, Chevron strives to build lasting relationships that support prosperity now and for decades to come. Through programs like our Chevron Humankind initiative, we’re able to offer meaningful support from our employees to their communities.

contribution to US nonprofits

$33.5M

charitable organizations

1,432

volunteer hours

92,829

more on community

contact information

1400 Smith Street

Houston, TX 77002, USA

Telephone: +1 832-854-1000

Send an Email

For the latest figures, view the 2024 Supplement to the Annual Report.

Chevron is dedicated to fostering open communication and providing a clear, accessible way for community members to share their thoughts, ask questions, or raise concerns. Contact us at GOMBUPGPA@chevron.com, and we will reply as quickly as possible.